With 35 years of experience in the aluminium welding wire manufacturing industry, Chuanwang has provided high-quality welding materials and services to over 5,000 companies. Our welding wires are trusted by customers worldwide, with successful shipments to 15 countries, earning us extensive international recognition and a reputation for reliability and excellence.

Pure aluminium welding wire, with an aluminium content greater than 99%, is known for its excellent conductivity, corrosion resistance, and a combination of plasticity and toughness. It is primarily used in aluminium plants and power plants for welding and processing applications.

Since producing the first batch of bright scraped aluminium welding wire in China in 2007, Zhengzhou Chuanwang has supplied welding wire to several large aluminium plants across China. Some of our notable projects include:

Additionally, we continue to provide over 20 tons of welding wire each month for ongoing maintenance in aluminium plants, supporting both infrastructure and repair needs.

Chuanwang has also made significant contributions to the power plant industry, providing 1070 welding wire for major power plants since 2009. Notable projects include:

In total, Chuanwang has supplied over 2300 tons of welding wire to these major power projects, helping to ensure the smooth operation and construction of critical power infrastructure.

As the market continues to grow, 1070 welding wire has also gained popularity in the medical industry, where Chuanwang provides high-quality welding wire for interventional medical devices.

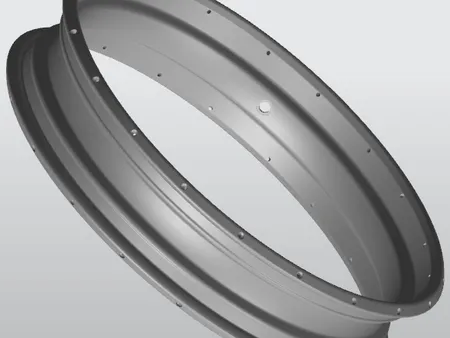

Aluminium-silicon welding wire is one of the most commonly used alloys in the aluminium welding industry. With the advancement of global industrial applications, it is widely used in the automotive industry for components such as car doors, windows, bodies, bumpers, crash beams, battery trays, fuel tanks, radiators, and wheels.

Since the production of the first batch of drum-packaged aluminium welding wire in China in 2018, Chuanwang has made significant contributions to the automated welding of new energy vehicles, providing nearly 2000 tons of welding wire to international automotive manufacturers. Key clients include Tesla, GAC Group, NIO, BAIC New Energy, Geely Group, Honda, Toyota, Mitsubishi, Dongfeng Nissan, and other well-known car manufacturers.

Car doors, windows, bumpers, crash beams, battery trays

Automotive aluminium radiators, intercoolers, fuel tanks, gas tanks

Outdoor furniture

Aluminium-magnesium alloy welding wire is widely used due to its corrosion resistance, lightweight properties, and high strength. It is frequently applied in industries such as automotive manufacturing, aerospace, shipbuilding, pressure vessels, and petrochemical applications.

As customer demands for weld strength, corrosion resistance, and lightweight materials continue to rise, aluminium-magnesium alloy welding wire is increasingly used in the production of new energy vehicles. Globslly reknowned automotive brands, including Tesla, GAC Group, NIO, BAIC New Energy, Geely Group, Honda, Toyota, Mitsubishi, and Dongfeng Nissan, have upgraded to using this alloy to improve vehicle performance and reliability.

Chuanwang has supplied aluminium-magnesium welding wire to numerous pressure vessel projects, including:

Aluminium-magnesium alloy welding wire has also been applied in several petrochemical projects, such as:

We’re here to help you navigate our range of welding wires and rods and find the best fit for your application. Reach out anytime: sales@cwhj.com