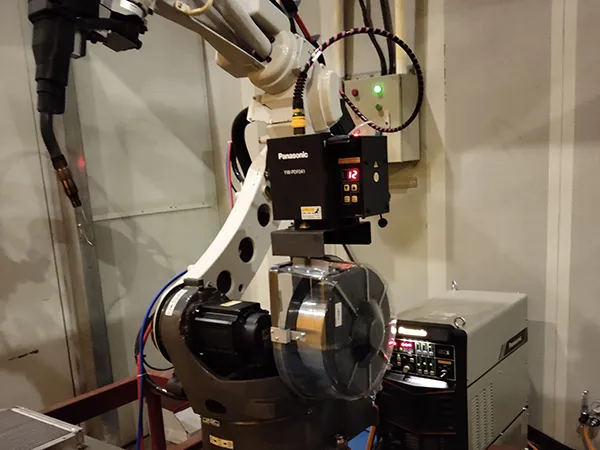

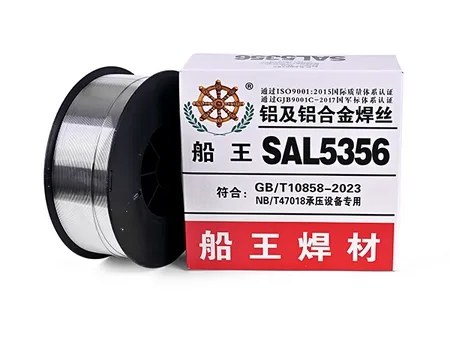

MIG welding, or metal inert gas welding, uses a consumable wire electrode and an inert gas, such as Argon (Ar) or Helium (He), to shield the weld area from contaminants. MIG welding requires specific properties for the welding wire to ensure smooth, reliable results:

We’re here to help you navigate our range of welding wires and rods and find the best fit for your application. Reach out anytime: sales@cwhj.com